Wear protection for tools

Increase of service life time - Reduction of maintenance intervals - Reduction of operating costs

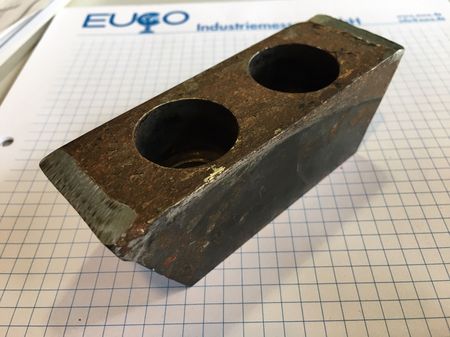

Wear resistance through hard application of cutting edges or wear protection of highly stressed surfaces in the interior of the shredding unit using several layers of welding wire. The hard application is applied by wire in layers.

- Reworking the worn tool → Hardfacing / hard application of the cutting edge → Reshaping / dimensioning of the geometry.

- Wear protection for clamping plates, counter knife slides, knife holders or counter knife strips.

- Rework instead of scrapping.

Areas of application:

- EBS processing or shredding of waste

- shredding of waste wood

- plastic processing

- etc.